What's the difference between Expulsion Fuses and Current-limiting Fuses?

Expulsion fuses are commonly used in utilities but much less frequently at industrial sites. So, for those who are scratching their heads wondering about the difference, here's a quick summary:

How do Expulsion Fuses and Current-limiting fuses interrupt current?

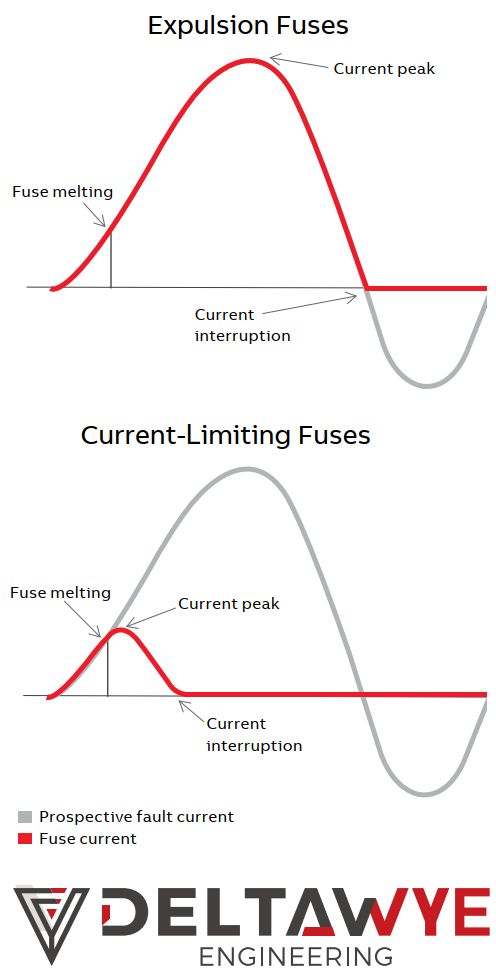

Expulsion Fuses: Expulsion Fuses interrupt the fault once the current and time exceed its rating (according to the TCC published by the manufacturer) but don’t interrupt the current until a zero crossing occurs, regardless of the fault current. In Expulsion Fuses, the fuse element immediately starts to melt, but the arcing continues and is contained in the fuse until a zero crossing.

Current-limiting Fuses: Contrary to Expulsion Fuses, Current-limiting fuses start to interrupt fault current immediately after the fuse melts, typically occurring within 1/2 cycle of the fault initiation for faults in the current limiting region. During a fault, a long fuse element (contained within a cooling medium, typically sand) melts.

The waveforms below illustrate the current during a current interruption for both an Expulsion Fuse and a Current-limiting fuse:

Why does this matter?

Current-limiting fuses prevent the current from reaching its prospective peak value, which can protect downstream devices rated to lower maximum fault currents. It also limits magnetic forces due to extremely high fault currents.

The energy released into the fault is proportional to the length of the fault and the square of the fault current (I2t). Therefore, Current-limiting fuses reduce the amount and duration of the voltage drop caused by fault currents.

Conclusion: Is one type better than the other?

Not necessarily. However, current-limiting fuses tend to be very good in applications where the goal is to limit the energy with high-fault currents. Otherwise, they have different advantages and disadvantages for different applications. They can be used in series, which can make sense in some applications.